SpreadLogic

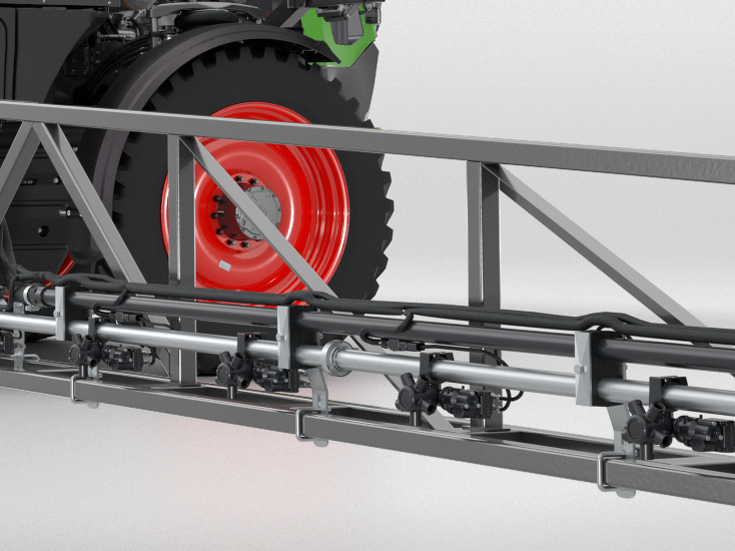

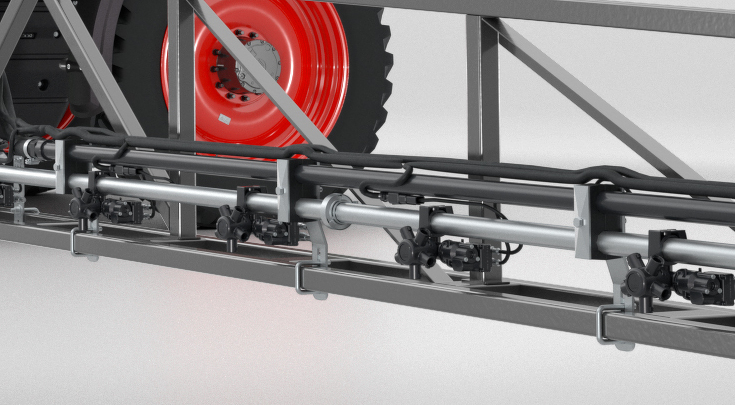

SpreadLogic™ encompasses many new features and significant changes to the delivery system, including UltraSpread™, TurnLogic™ and a modular boom.

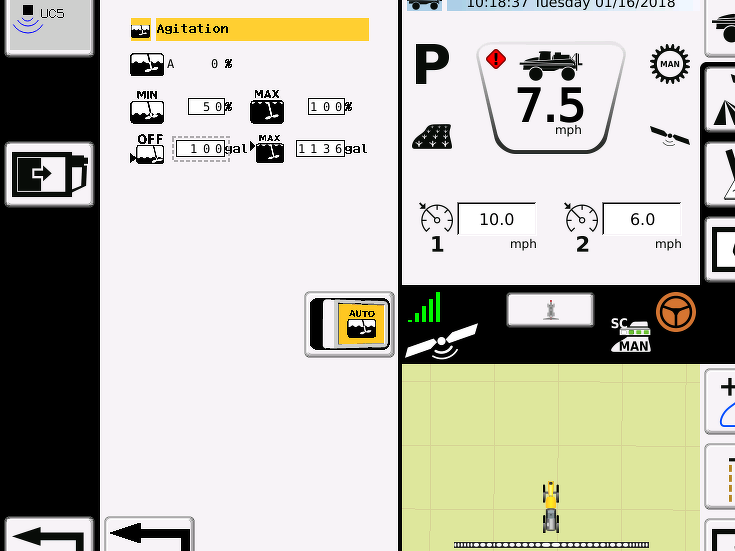

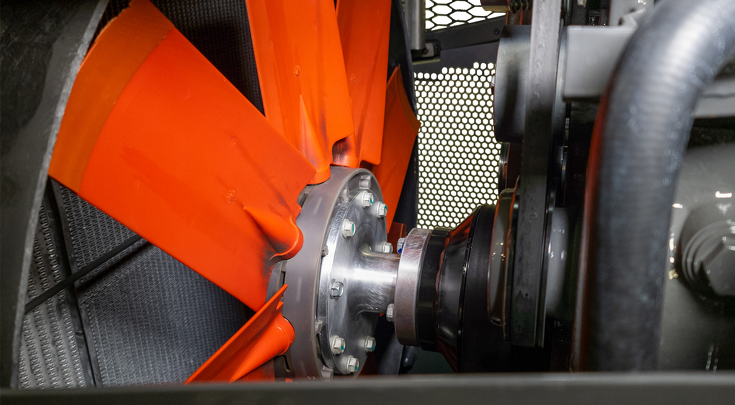

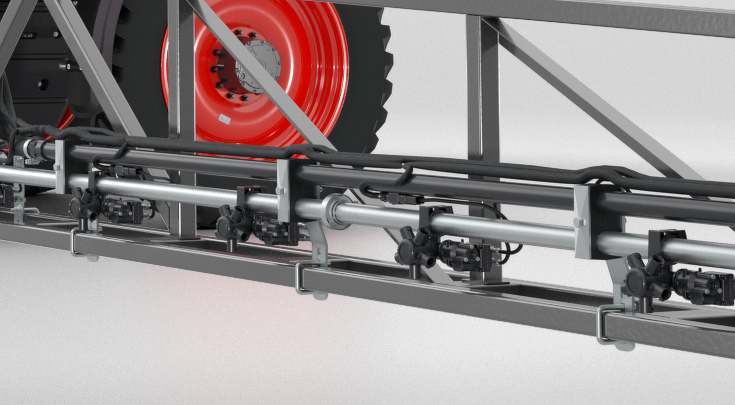

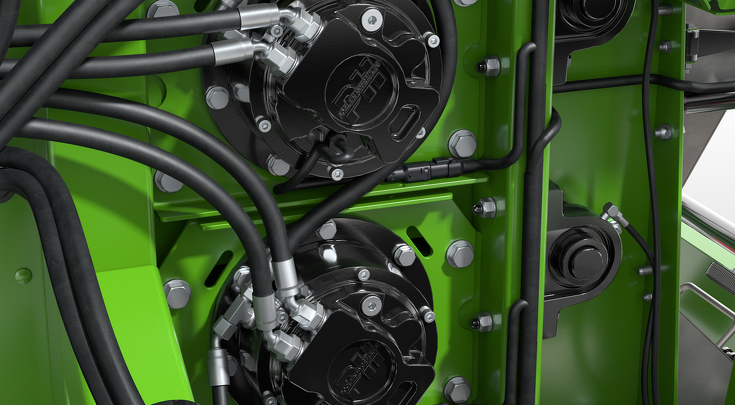

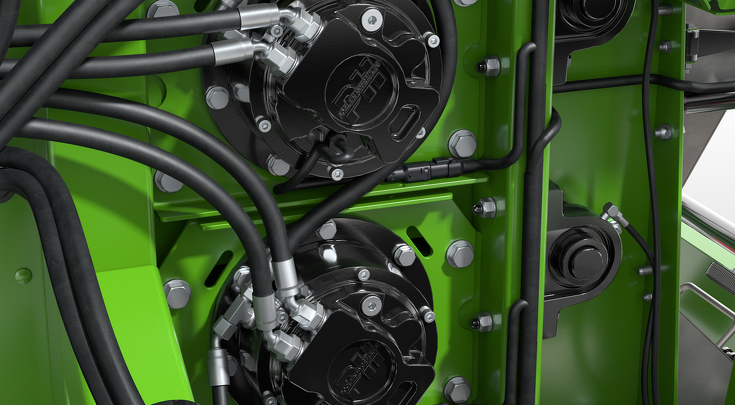

The low speed and high torque provided by UltraSpread’s radial piston hydraulic motors permit the conveyor chain to maintain consistent slow or fast motion under the load of product in the box, unlike gearbox designs that struggle to perform under load and at low rates.

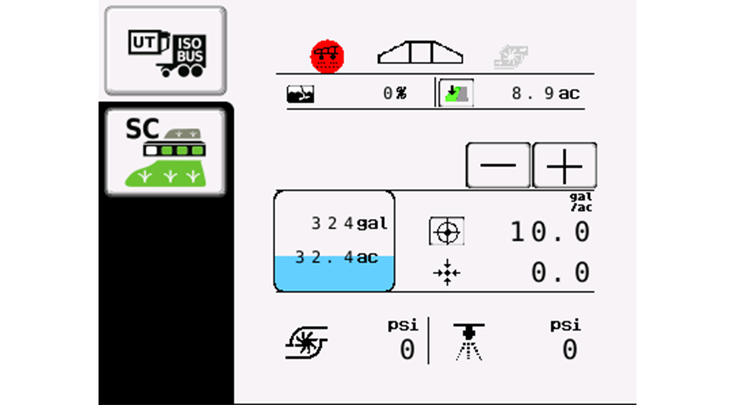

- The rate sensors use 888 pulses per revolution, which provides 150% more pulses for every degree of rotation, increasing the accuracy of the overall product control.

- The UltraSpread motors support a large rate range, which eliminates the need for operators to change any box settings in order to apply throughout the window.

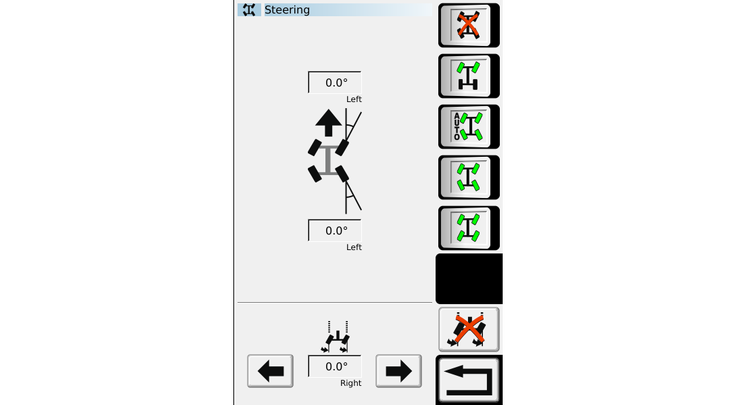

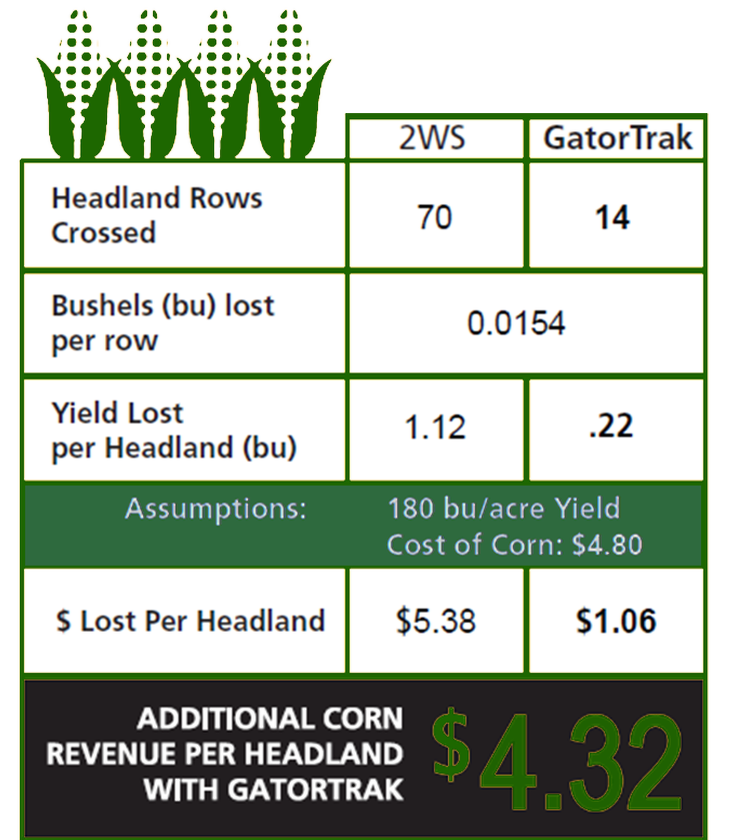

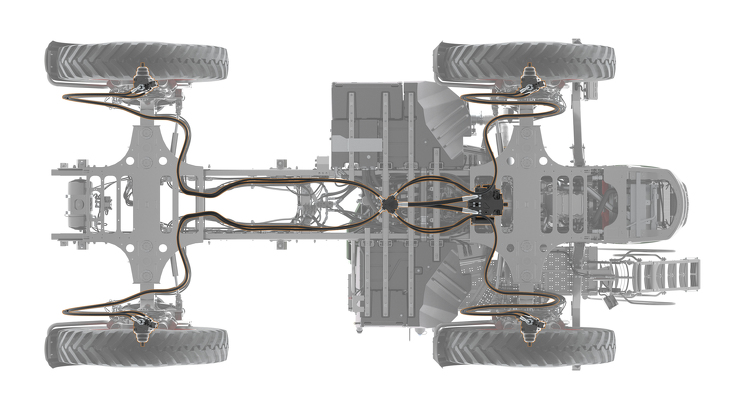

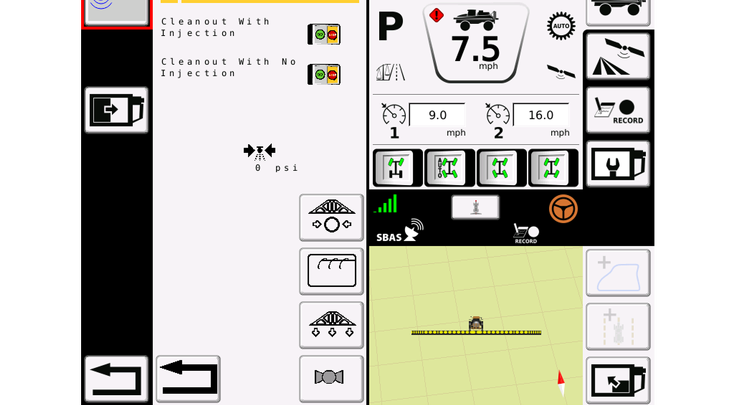

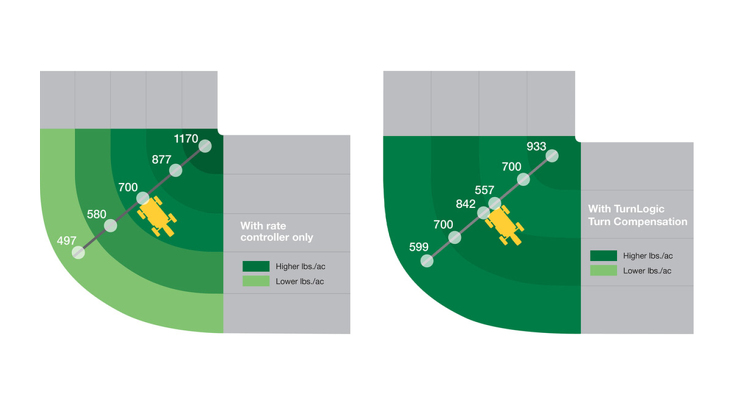

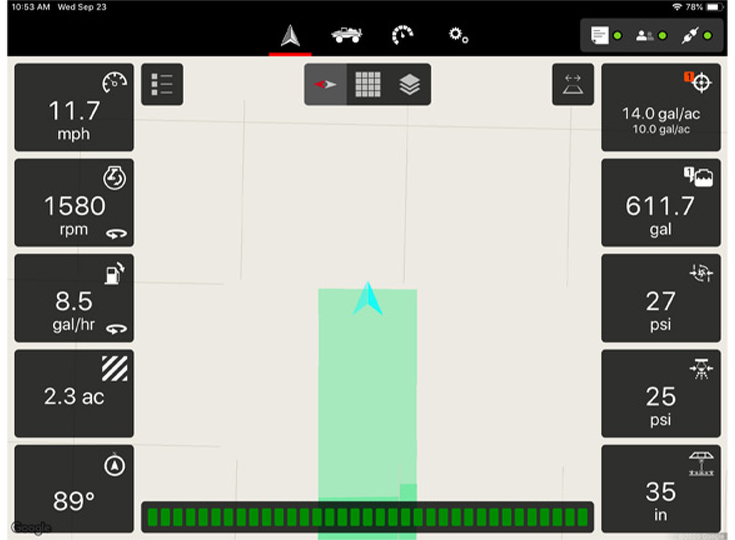

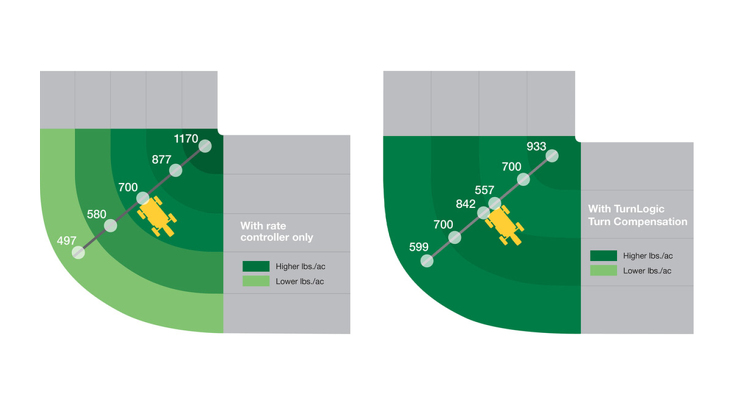

Agronomic accuracy is about proper product placement, soil health and yield improvement. TurnLogic automatically adjusts distribution rates to ensure even coverage during cornering. Rate is automatically controlled from the center point on each boom wing, adjusting up or down (based on the position of the steering axles) to ensure even fertilizer distribution over any curve. Continuous under- and over-application in the same spot over time can lead to plant lodging or soil nutrient deficits and result in yield reductions. TurnLogic helps maximize yields while improving soil and plant health.

Parts Kits

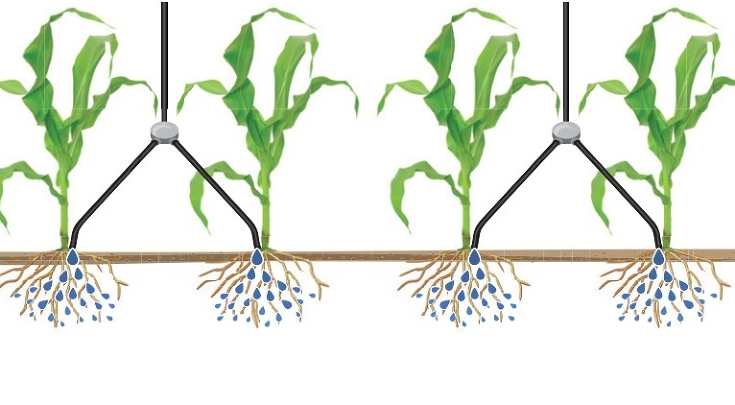

Drop hoses can be purchased through AGCO Parts to place late-season nitrogen or cover crops between the rows and below the crop canopy. This increases effectiveness of the application and prevents fertilizer or seed from becoming trapped in the whorl of the plant.

Parts Kits

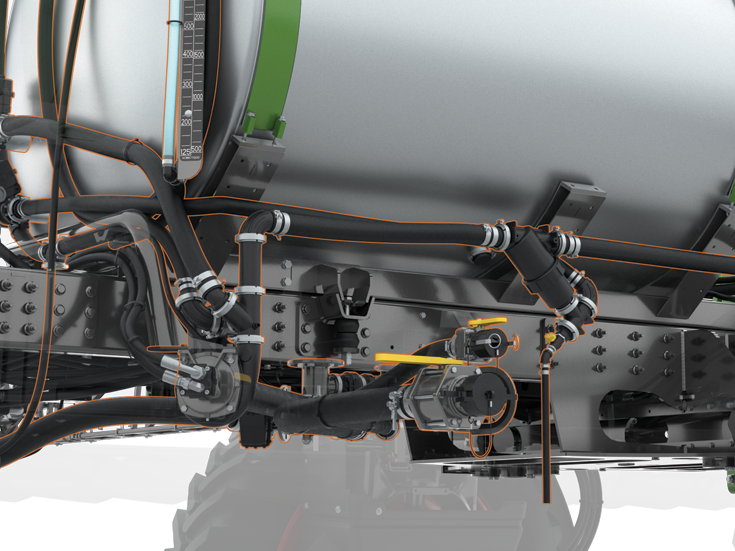

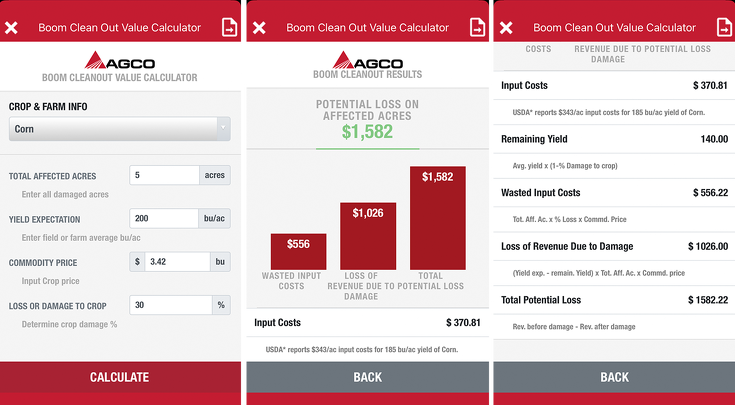

Recon SpreadSense® is an acoustic sensor that provides real-time flow detection through a pneumatic spreader. Sensors installed on the back of each deflector monitor material flow and send sound pulses to an ECU, which then displays blockage information on an iPad® in the cab.

- This system has proven to reduce operator stress and prevent misapplications due to plugged nozzles.